Model Scenery and Structure offers layout fabrication to any level of completion from ‘track only’ to sophisticated works of art with scenery, structures, signals, lighting, backdrops and the latest in computer controlled operation. The Build alone can cost from ‘thousands’ to ‘hundreds of thousands’ of dollars. Layout size, complexity and operational functions along with the level of completion will determine the cost. Generally, as a rule of thumb, the labor will be about three to five times the cost of materials and components. Model Scenery and Structure is proud to create high quality yet affordable model railroads.

We use high quality materials and products from industry leading manufacturers and produce highly reliable, craftsman quality layouts. This philosophy provides you with a great looking, low maintenance Model Railroad that brings your dream to reality. As in the design phase we will collaborate with you to determine the components and level of completion to be incorporated in the layout. A Build Proposal that includes a Build Scope of Work, Material List and Timeline will be developed incorporating details from the Layout Plan Set.

Levels of Completion

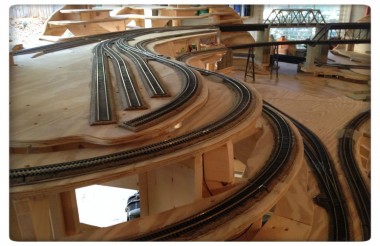

Bench, Track & Operational

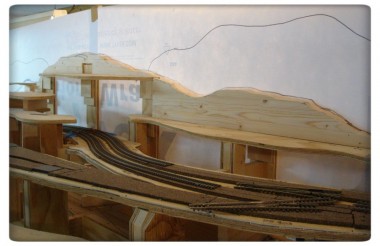

- Bench work with track elevations and topography integrated on the deck

- Track installed and wiring for DC or DCC operation roughed out

- Operational components installed and wiring roughed out

- Power and control components installed, all wiring completed, tested

- Computer Control integrated, data input and tested

Levels of Completion

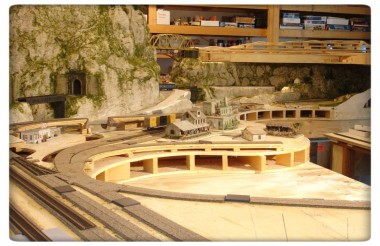

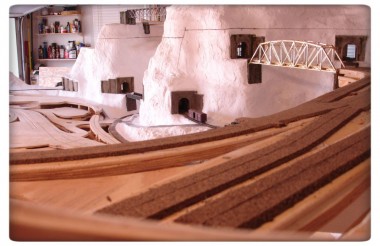

Scenery and Structure Levels

- Basic ground cover on flat and elevated terrain

- Bridges, abutments and portals installed

- Structures installed (your prebuilt collection)

- Structures built by us and installed

- Complete scenery including bushes, trees, bodies of water and roadways

- Backdrops fabricated and painted

Proven Methods – Quality Products

The team assembled by Model Scenery and Structure bring to the table years of model railroading and model making experience. Their uncompromising attention to detail, established disciplines and quality control standards are reflected in every project. Materials are chosen for their quality and reliability with proven performance from leading manufacturers in the industry. We always choose products made in the USA when available.

This combination of skilled staff and the best products coupled with our in-depth research, comprehensive planning and our strict design standards produce models and layouts that are among the finest in the industry.

Model Scenery and Structure applies modern techniques along with tried and true hands on modeling practices in the fabrication of our models. Although this approach may be more labor intensive we believe the advantage of this method is reflected in the details and overall appearance of the finished product.

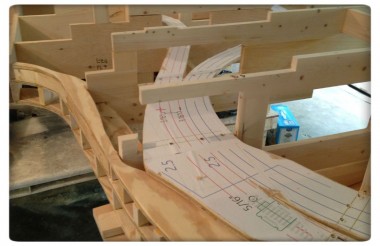

Diligent Planning To be cost effective and offset the labor intensive handmade elements on the layout bench and deck framework we use the Layout Plan Set and our unique Modular System to fabricate the bench structure. This process saves time in fabrication and facilitates delivery and installation. The CadRail drawings are used for the benchwork plans and patterns, track roadbed diagrams, scenery and structure plans, electrical schematics, digital component diagrams depicting component locations, digital addresses and wiring connection points and the control station design. The detail plans allow us to compete with laser cutting systems, particularly with one of a kind projects where repetitive cutting of the same component project to project is not required. Our team utilizing these techniques, technologies and standards along with their extensive skills to create the masterpieces we are proud to tag ‘Created by Model Scenery and Structure’.

Build Proposal

The Build Proposal will include the complete project cost with all materials and labor included. Once agreed upon there will be NO EXTRA COSTS to complete your layout! If major changes are made at your request additional costs, or credits may be applied. Shipping, crating, delivery and installation costs are NOT included in the Build Proposal.

A fee to prepare the Build Proposal based on the layout complexity and level of completion will be presented. The fee is determined by the number of hours required to prepare the Build Proposal. This can run from eight hours to sixty hours or more on large projects. The fee will be ‘applied as a credit to the total project cost’ indicated on the completed Build Proposal when you approve the project. If the project is shelved the fee remains with Model Scenery and Structure. Development of the Build Proposal will begin as scheduled upon fee payment.

Together we will review the completed Build Proposal. If major changes are made, like changing the level of completion, an additional fee may be required to revise the Build Proposal. When you’re satisfied that the Build Proposal accurately represents your expectations we will establish a payment structure. Generally, a deposit is made to get the project scheduled with the first payment due when work starts. Subsequent payments are structured to coincide with a specific stages of project completion. The payment structure will be incorporated into the Build Proposal. Once the Build Proposal is signed off we’re ready to move forward. The Build will be scheduled with receipt of a deposit or payment as defined in the Build Proposal.